Products-1: VARIOUS INDUSTRIAL DIAMONDS

About Syntek’s Diamond Products

First of all, thank you very much for visiting our website.

You might have checked various other companies before you are here.

If you are tired of searching good industrial diamonds, this coming may make you worthwhile finally.

What kind of tools or parts would you like to get? Or imaging and planning?

We will give you some typical examples that our diamonds are used to be.

Our diamonds have been used as optical parts, X-ray monochromator, cutting tools for CFRP (Carbon Fiber Reinforced Plastics) and Heat Sink for many years.

*Heat Sink hasn’t been so popular since 2015, we don’t know why.

Recently industrial diamonds are used for several core parts on artificial satellites and robots(especially nursing care ones).

We are afraid that it is difficult to tell you the details and show you photos (even drawings) of our items on this website because of we have several contracts between customers.

Hope you understand our position.

If you are belonging to one of the above products or if you are planning or researching those items, please let us know.

Even if you are doing other items, it is no problem for supporting.

If you are aiming to be an “absolutely essential” in the near future, it might be a good idea to cooperate together.

We look forward to getting your message!

Syntek’s Regular Items

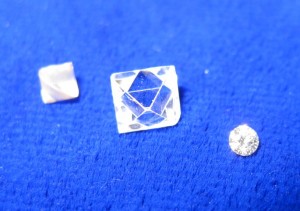

| ①Single Crystal Diamond | |

|---|---|

|

It is clear crystal. You have seen it a lot as jewels. Single crystal diamond is essential material for superfine processing tools. Yellow color man-made diamond is used for industrial diamond, too. Single crystal diamond has a 10-to-1 advantage over other materials at thermally, technologically, mechanically, and electrically parts. And it is also superior to corrosion resistance. Single crystal diamond is subject to considerable research such as “extreme material.” ◆Main uses: Mirror like finishing, surface roughness in nano-level, high accurate, atomization, medica products, and more |

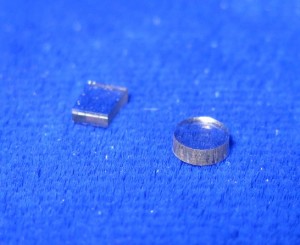

| ②PCD (Polycrystalline Diamond) | |

|---|---|

|

PCD is basically made by diamond powder and metal binder with high-pressure(5GPa) and high-temperature (1500 degree/Celsius). PCD’s hardness level is less than single crystal diamond, but it has workability than single crystal diamond. And PCD has also conducting properties, then PCD is used for abrasion-resistant parts and others. PCD is softer than single crystal diamond, but still 4 times harder than WC (tungsten carbide). About abrasion-resistant, PCD is several times superior to WC. Main uses: |

| ③CVD Diamond | |

|---|---|

|

CVD stands for “Chemical Vapor Deposition.” Chemical vapor deposition of diamond has received a great deal of attention in the materials sciences because it allows many new applications of diamond that had previously been considered too difficult to make economical. CVD diamond growth typically occurs under low pressure (1-27 kPa; 0.145-3.926 psi; 7.5-203 Torr) and involves feeding varying amounts of gases into a chamber, energizing them and providing conditions for diamond growth on the substrate. Main uses: |

| ④DLC Coating | |

|---|---|

|

DLC (Diamond-like carbon) exists in seven different forms of amorphous carbon materials that display some of the unique properties of natural diamond. They are usually applied as coatings to other materials that could benefit from some of those properties. The hardest, strongest, and slickest is such a mixture, known as tetrahedral amorphous carbon. Main uses: |

| ⑤Diamond Powder | |

|---|---|

|

Literally, diamond powder is very tiny powder. We provide this powder from 0.5 to 34.4-micron meter in diameter. If you need nano-size, it is possible to prepare. Please ask us specific size. This diamond powder is mainly used for polishing. |

| ⑥PROCESSING WITH DIAMOND | ||

|---|---|---|

| Diamond End Mill | Diamond Window | Antiwear Parts |

|

|

|

| Single crystal diamond φ0.4 | Part for Laser equipment | PCD |

| Brilliant Cut | Indenter | Laser Processing |

|

|

|

| Natural and Man-made | 60° Edge Pyramid | Shaping(1scale=1mm) |

Others

・Point Scribe(3points and 4points)

・Bercovici indenter

・Contact

・Tip Mounter Head

・Sawing